In today’s competitive landscape, maintaining high-quality products and services is no longer a luxury; it’s a necessity for survival. Businesses are constantly seeking ways to streamline their operations, reduce errors, and ensure consistent quality across all processes. This is where Enterprise Resource Planning (ERP) systems integrated with quality management functionalities come into play. Having personally overseen the implementation of ERP systems in several organizations, I’ve witnessed firsthand the transformative impact it can have on a company’s quality control and overall efficiency.

Many businesses still rely on disparate systems and manual processes to manage quality, which often leads to data silos, communication breakdowns, and increased risk of errors. This fragmented approach makes it difficult to track key performance indicators (KPIs), identify root causes of quality issues, and implement effective corrective actions. An ERP system with robust quality management capabilities offers a centralized platform to manage all aspects of quality, from initial design to final product delivery, providing real-time visibility and control over the entire quality lifecycle.

This guide will provide a comprehensive overview of ERP for quality management, exploring its key features, benefits, implementation considerations, and how to select the right solution for your specific business needs. We’ll delve into the practical aspects of integrating quality management into your ERP system, drawing on real-world examples and lessons learned from successful implementations. Whether you’re just starting to explore the potential of ERP or looking to optimize your existing system, this guide will equip you with the knowledge and insights you need to achieve quality excellence.

What is ERP for Quality Management?

ERP for Quality Management refers to the integration of quality control processes and functionalities directly within an Enterprise Resource Planning (ERP) system. Instead of relying on separate, disconnected systems for quality management, an ERP system centralizes and streamlines all quality-related activities. This integration provides a holistic view of the entire value chain, allowing businesses to proactively identify and address potential quality issues throughout the product lifecycle.

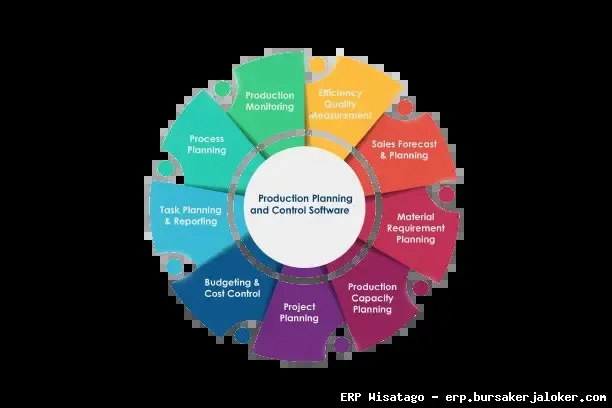

Key Components of ERP Quality Management

An effective ERP quality management module typically includes the following core components:

- Quality Planning: Defining quality standards, specifications, and inspection procedures for products and processes.

- Quality Control: Monitoring and measuring quality performance against established standards, using tools like statistical process control (SPC) and inspection reports.

- Quality Assurance: Implementing preventative measures to ensure that products and processes consistently meet quality requirements. This includes activities like supplier audits, process validation, and training.

- Non-Conformance Management: Identifying, documenting, and resolving non-conformances or defects. This involves root cause analysis, corrective and preventive actions (CAPA), and tracking the effectiveness of implemented solutions.

- Audit Management: Planning, conducting, and documenting internal and external audits to assess compliance with quality standards and regulations.

- Document Control: Managing and controlling all quality-related documents, including procedures, specifications, and records, ensuring that the latest versions are readily available and accessible to authorized personnel.

Benefits of Integrating Quality Management with ERP

Integrating quality management within your ERP system offers a multitude of benefits, leading to improved product quality, reduced costs, and increased customer satisfaction. Here are some of the key advantages:

Improved Visibility and Traceability

By centralizing all quality data within the ERP system, businesses gain complete visibility into the entire quality lifecycle. This allows for easy tracking of materials, processes, and products, enabling quick identification of the source of any quality issues. Traceability is crucial for regulatory compliance and allows for efficient product recalls if necessary.

Reduced Costs

ERP quality management can significantly reduce costs associated with poor quality, such as scrap, rework, and warranty claims. By proactively identifying and addressing potential quality issues early in the process, businesses can prevent defects from occurring in the first place. Furthermore, streamlined processes and reduced manual effort can lead to significant cost savings.

Enhanced Efficiency

Automating quality management processes within the ERP system eliminates manual tasks, reduces paperwork, and streamlines workflows. This improves efficiency and allows employees to focus on more value-added activities. Real-time data and analytics provide insights that enable faster decision-making and continuous improvement.

Better Compliance

Many industries are subject to strict quality regulations and standards. An ERP system with integrated quality management helps businesses comply with these regulations by providing a framework for documenting processes, tracking data, and generating reports. This simplifies audits and reduces the risk of non-compliance penalties.

Improved Customer Satisfaction

Ultimately, the goal of quality management is to deliver high-quality products and services that meet or exceed customer expectations. By integrating quality management with ERP, businesses can ensure consistent quality, reduce defects, and improve customer satisfaction. This leads to increased customer loyalty and positive word-of-mouth referrals.

Key Features to Look for in an ERP Quality Management Module

When selecting an ERP system with quality management capabilities, it’s important to consider the specific features that are essential for your business. Here are some key features to look for:

Real-Time Data and Analytics

The ERP system should provide real-time data and analytics on key quality metrics, such as defect rates, process capability, and supplier performance. This allows for proactive monitoring and identification of potential issues before they escalate.

Statistical Process Control (SPC)

SPC tools are essential for monitoring and controlling process variability. The ERP system should include SPC charts and analysis capabilities to help identify and address process instability.

Corrective and Preventive Action (CAPA) Management

A robust CAPA module is critical for managing non-conformances and implementing effective corrective and preventive actions. The system should allow for documenting non-conformances, conducting root cause analysis, tracking corrective actions, and verifying their effectiveness.

Audit Management

The ERP system should support the planning, scheduling, and execution of internal and external audits. It should also provide tools for documenting audit findings, tracking corrective actions, and generating audit reports.

Supplier Quality Management

Supplier quality is a critical component of overall product quality. The ERP system should include features for managing supplier performance, conducting supplier audits, and tracking supplier non-conformances.

Document Control

Effective document control is essential for maintaining compliance and ensuring that all employees have access to the latest versions of quality-related documents. The ERP system should provide a centralized repository for managing documents, controlling revisions, and tracking approvals.

Implementing ERP for Quality Management: Best Practices

Implementing ERP for quality management can be a complex project, but following best practices can significantly increase the chances of success. Here are some key considerations:

Define Clear Goals and Objectives

Before starting the implementation process, it’s crucial to define clear goals and objectives for the project. What specific quality improvements are you hoping to achieve? What KPIs will you use to measure success? Having a clear understanding of your goals will help guide the implementation process and ensure that the ERP system is configured to meet your specific needs.

Involve Key Stakeholders

ERP implementation is not just an IT project; it’s a business transformation project. It’s essential to involve key stakeholders from all departments, including quality, manufacturing, engineering, and finance. This ensures that the ERP system is aligned with the needs of all users and that everyone is committed to the success of the project.

Choose the Right ERP Vendor

Selecting the right ERP vendor is critical for success. Look for a vendor with experience in your industry and a proven track record of successful implementations. Make sure the ERP system has the specific quality management features you need and that it can be customized to meet your unique requirements.

Data Migration and Cleansing

Migrating data from legacy systems to the new ERP system can be a challenging task. It’s important to plan the data migration process carefully and ensure that the data is cleansed and validated before it’s loaded into the ERP system. Poor data quality can significantly impact the effectiveness of the ERP system.

Training and Support

Proper training and support are essential for ensuring that users can effectively use the ERP system. Provide comprehensive training to all users and offer ongoing support to address any questions or issues that may arise. A well-trained workforce is more likely to embrace the new system and use it effectively.

Continuous Improvement

ERP implementation is not a one-time event; it’s an ongoing process. Continuously monitor the performance of the ERP system and identify areas for improvement. Regularly review your quality processes and make adjustments as needed to ensure that the ERP system is meeting your evolving business needs.

Choosing the Right ERP System for Your Needs

Selecting the right ERP system for your business is a critical decision that can have a significant impact on your quality management capabilities. Here are some factors to consider when making your choice:

Industry-Specific Requirements

Some ERP systems are designed for specific industries and include features that are tailored to the unique needs of those industries. If you’re in a highly regulated industry, such as pharmaceuticals or aerospace, you’ll want to choose an ERP system that is compliant with relevant regulations.

Scalability

Choose an ERP system that can scale with your business as it grows. The system should be able to handle increasing volumes of data and transactions without compromising performance. For more information, you can refer to RMM as an additional resource.

Integration Capabilities

The ERP system should be able to integrate with other systems, such as your CRM, MES, and PLM systems. This will allow you to share data seamlessly across different departments and improve overall efficiency.

Cloud vs. On-Premise

Decide whether you want a cloud-based ERP system or an on-premise system. Cloud-based ERP systems offer several advantages, such as lower upfront costs, easier maintenance, and greater scalability. However, on-premise systems may be a better choice for businesses with specific security or compliance requirements.

Vendor Reputation and Support

Choose an ERP vendor with a strong reputation and a proven track record of successful implementations. Make sure the vendor offers comprehensive support and training to help you get the most out of your ERP system.

By carefully considering these factors, you can choose an ERP system that will meet your specific needs and help you achieve your quality management goals. Remember to thoroughly research potential vendors, request demos, and talk to other businesses that have implemented similar systems. With the right ERP system in place, you can transform your quality management processes and achieve significant improvements in product quality, efficiency, and customer satisfaction.

Frequently Asked Questions (FAQ) about ERP for quality management

How does implementing an ERP system specifically improve quality control processes within a manufacturing company?

Implementing an ERP system offers significant improvements to quality control in manufacturing. First, it provides centralized data management, ensuring all quality-related information, like inspection results, non-conformance reports, and corrective actions, is stored in one location. This enhances traceability and reduces errors associated with manual data entry. Second, ERP systems automate many quality control processes, such as statistical process control (SPC) and incoming inspection, leading to faster detection of defects and deviations. Third, an ERP system improves real-time visibility into the entire production process, allowing for proactive identification and resolution of potential quality issues. Finally, by integrating quality data with other business functions like purchasing and production planning, ERP systems facilitate root cause analysis and prevent future quality problems, ultimately reducing waste and improving customer satisfaction.

What are the key features to look for in an ERP system when focusing on quality management and regulatory compliance like ISO 9001?

When selecting an ERP system for quality management and regulatory compliance (e.g., ISO 9001), several key features are essential. Document control is paramount; the system should manage revisions, approvals, and access to quality documents. Audit trail capabilities are crucial for tracking changes and ensuring accountability. The ERP should support non-conformance management, enabling the recording, investigation, and resolution of defects. Integration with statistical process control (SPC) tools is vital for monitoring process performance and identifying trends. Look for features that facilitate calibration management for equipment. Furthermore, the system should support CAPA (Corrective and Preventive Action) processes, allowing for systematic problem-solving and continuous improvement. Finally, ensure the ERP system offers robust reporting and analytics to monitor key quality metrics and demonstrate compliance to auditors.

How does using an ERP system for quality management help reduce costs associated with poor quality and product recalls?

An ERP system significantly reduces costs related to poor quality and product recalls through several mechanisms. By providing real-time data and analytics, ERP systems enable early detection of quality issues, preventing defects from escalating and reducing scrap and rework costs. Improved traceability allows for quick identification of affected products in case of a recall, minimizing the scope and expense of the recall. The system’s CAPA (Corrective and Preventive Action) functionality facilitates root cause analysis and prevents recurrence of quality problems, reducing future costs associated with defects. By automating quality control processes, ERP systems reduce manual errors and improve efficiency, leading to lower labor costs. Finally, by integrating quality data with other business functions, ERP systems improve overall process efficiency and reduce waste, further minimizing costs related to poor quality and potential product recalls.