Imagine running a manufacturing plant where every department operates in its own silo. The sales team is promising delivery dates the shop floor can’t meet, inventory is either overflowing or completely depleted, and accounting is struggling to reconcile transactions across disparate systems. This chaotic scenario is all too common in manufacturing businesses still relying on outdated or disconnected software. That’s where Enterprise Resource Planning (ERP) systems come in. ERP offers a centralized platform to manage and integrate all core business processes, from planning and production to inventory management and finance.

Implementing an ERP system is a significant undertaking, often requiring substantial investment and careful planning. It’s not simply a matter of installing software; it’s about transforming the way your business operates. The right ERP solution can streamline processes, improve efficiency, reduce costs, and provide real-time visibility into every aspect of your manufacturing operations. However, choosing the wrong system or implementing it poorly can lead to costly delays, frustrated employees, and ultimately, a failed project. I’ve seen firsthand the transformative power of ERP, and also the pitfalls of a poorly executed implementation. This guide is designed to provide you with a comprehensive understanding of ERP software for manufacturing, helping you navigate the complexities and make informed decisions for your business.

This article will delve into the core features of manufacturing ERP systems, explore the benefits they offer, discuss common challenges faced during implementation, and provide practical advice on selecting the right solution for your specific needs. Whether you’re a small job shop or a large-scale manufacturer, understanding the capabilities of modern ERP systems is crucial for staying competitive in today’s demanding market. Let’s embark on this journey to unlock the potential of ERP and transform your manufacturing operations.

ERP Software For Manufacturing: Complete Guide, Features and Details

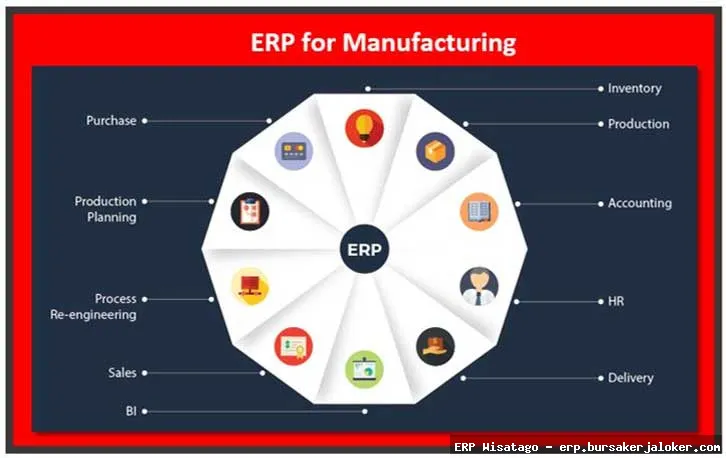

ERP software for manufacturing is a comprehensive suite of integrated modules designed to manage and automate various aspects of a manufacturing business. It moves beyond basic accounting or inventory management to encompass everything from product design and development to supply chain management and customer relationship management. The goal is to create a single source of truth for all business data, enabling better decision-making, improved efficiency, and enhanced collaboration across departments.

Core Modules and Functionality

A robust manufacturing ERP system typically includes the following core modules:

- Materials Management: This module focuses on managing inventory levels, tracking raw materials, components, and finished goods. It includes functionalities such as purchase order management, receiving, shipping, and inventory control. Effective materials management helps minimize waste, reduce carrying costs, and ensure timely availability of materials for production.

- Production Planning and Control: This is the heart of the manufacturing ERP system. It encompasses everything from demand forecasting and master production scheduling (MPS) to capacity planning and shop floor control. The module helps optimize production schedules, allocate resources effectively, and track work-in-process (WIP) inventory.

- Shop Floor Control: This module provides real-time visibility into shop floor operations. It allows you to track production progress, monitor machine utilization, manage labor costs, and identify bottlenecks. Features like barcode scanning, machine integration, and real-time data collection enable accurate tracking and improved efficiency.

- Quality Management: Maintaining product quality is paramount in manufacturing. The quality management module helps you establish and enforce quality standards, track inspections, manage non-conformances, and implement corrective actions. This module ensures that products meet the required quality standards and reduces the risk of defects and recalls.

- Finance and Accounting: This module integrates all financial data from other modules, providing a comprehensive view of the company’s financial performance. It includes functionalities such as general ledger, accounts payable, accounts receivable, budgeting, and cost accounting. Accurate financial data is crucial for making informed business decisions and ensuring compliance with regulations.

- Supply Chain Management (SCM): This module extends beyond the four walls of the manufacturing plant to encompass the entire supply chain. It includes functionalities such as supplier management, demand planning, transportation management, and logistics. Effective SCM helps optimize the flow of materials and information, reduce lead times, and improve customer satisfaction.

- Customer Relationship Management (CRM): This module focuses on managing customer interactions and improving customer satisfaction. It includes functionalities such as sales force automation, marketing automation, and customer service management. A strong CRM system helps you build stronger customer relationships, increase sales, and improve customer retention.

- Engineering and Product Data Management (EPDM): This module manages product designs, engineering changes, and bills of materials (BOMs). It ensures that everyone is working with the latest version of the product design and that all changes are properly documented and approved. This module is critical for maintaining product quality and reducing the risk of errors.

Benefits of Implementing Manufacturing ERP

Implementing a manufacturing ERP system can offer numerous benefits, leading to improved efficiency, reduced costs, and increased profitability. These benefits extend across all areas of the business, from the shop floor to the executive suite.

Improved Efficiency and Productivity

By automating manual processes and integrating disparate systems, ERP can significantly improve efficiency and productivity. For example, automating purchase order creation and approval can save time and reduce errors. Real-time visibility into inventory levels can prevent stockouts and reduce carrying costs. Streamlined production scheduling can optimize resource allocation and minimize downtime. These improvements translate into higher output, lower costs, and increased profitability.

Reduced Costs

ERP can help reduce costs in several ways. By optimizing inventory levels, you can reduce carrying costs and minimize waste. By streamlining production processes, you can reduce labor costs and improve machine utilization. By improving quality control, you can reduce the risk of defects and recalls. By automating financial processes, you can reduce administrative costs. These cost savings can have a significant impact on the bottom line.

Enhanced Visibility and Decision-Making

ERP provides real-time visibility into all aspects of the manufacturing operation, from inventory levels to production progress to financial performance. This visibility enables better decision-making at all levels of the organization. For example, sales managers can see real-time inventory levels and production schedules to provide accurate delivery dates to customers. Production managers can see real-time shop floor data to identify bottlenecks and optimize resource allocation. Executives can see real-time financial data to make informed strategic decisions.

Improved Customer Satisfaction

By improving efficiency and providing accurate delivery dates, ERP can enhance customer satisfaction. Customers appreciate knowing when they can expect their orders to arrive. By improving product quality, you can reduce the risk of defects and returns, further enhancing customer satisfaction. A strong CRM module within the ERP system can also help you build stronger customer relationships and provide better customer service.

Streamlined Compliance

Many manufacturing industries are subject to strict regulations. ERP can help you streamline compliance by providing a centralized system for tracking data and generating reports. For example, ERP can help you comply with environmental regulations by tracking emissions and waste disposal. It can also help you comply with safety regulations by tracking employee training and safety inspections. Streamlined compliance reduces the risk of fines and penalties and improves the company’s reputation.

Challenges of ERP Implementation

While the benefits of ERP are substantial, the implementation process can be challenging. It’s important to be aware of these challenges and plan accordingly to mitigate the risks.

High Costs

ERP implementation can be expensive, involving software licensing fees, hardware costs, implementation services, and training costs. It’s important to carefully evaluate the total cost of ownership (TCO) before making a decision. Consider not only the initial costs but also the ongoing maintenance and support costs.

Complexity

ERP systems are complex, with many modules and functionalities. Implementing and configuring the system can be challenging, requiring specialized expertise. It’s important to choose an ERP vendor with experience in your industry and a proven track record of successful implementations.

Resistance to Change

ERP implementation often requires significant changes in business processes. Employees may resist these changes, especially if they are not properly informed and trained. It’s important to communicate the benefits of ERP to employees and involve them in the implementation process. Provide adequate training and support to help them adapt to the new system.

Data Migration

Migrating data from legacy systems to the new ERP system can be a complex and time-consuming process. It’s important to plan the data migration carefully and ensure that the data is accurate and complete. Data cleansing and validation are crucial steps to ensure data integrity. Effective IT management often relies on a robust system, and RMM plays a crucial role in that process

.

Integration with Existing Systems

ERP systems often need to be integrated with other existing systems, such as CRM, SCM, or e-commerce platforms. This integration can be challenging, requiring specialized expertise. It’s important to choose an ERP vendor that has experience integrating with the systems you use.

Choosing the Right ERP Solution

Selecting the right ERP solution is crucial for a successful implementation. Here are some factors to consider:

Industry-Specific Functionality

Choose an ERP system that is specifically designed for the manufacturing industry. These systems will have features and functionalities that are tailored to the unique needs of manufacturers, such as BOM management, shop floor control, and quality management.

Scalability

Choose an ERP system that can scale with your business. As your business grows, your ERP system should be able to handle increasing data volumes and user loads. Consider cloud-based ERP solutions, which offer greater scalability and flexibility than on-premise solutions.

Ease of Use

Choose an ERP system that is easy to use and intuitive. A user-friendly system will make it easier for employees to adopt the new system and improve their productivity. Look for systems with a modern user interface and comprehensive training materials.

Vendor Reputation and Support

Choose an ERP vendor with a strong reputation and a proven track record of successful implementations. Look for vendors that offer comprehensive support and training services. Check customer reviews and references to get a sense of the vendor’s capabilities and customer satisfaction.

Cost

Carefully evaluate the total cost of ownership (TCO) of the ERP system. Consider not only the initial costs but also the ongoing maintenance and support costs. Compare the costs of different ERP systems and choose the one that offers the best value for your money.

Cloud vs. On-Premise

Decide whether you want a cloud-based or on-premise ERP system. Cloud-based systems offer greater scalability and flexibility, while on-premise systems offer greater control over data security. Consider the pros and cons of each option and choose the one that best meets your needs.

Conclusion

Implementing ERP software for manufacturing is a strategic investment that can transform your business. By understanding the core features, benefits, challenges, and selection criteria, you can make informed decisions and choose the right solution for your specific needs. Remember to plan carefully, involve employees in the implementation process, and provide adequate training and support. With the right ERP system and a well-executed implementation, you can streamline your operations, reduce costs, improve customer satisfaction, and gain a competitive advantage in today’s demanding market. Don’t be afraid to seek expert advice and guidance throughout the process. The journey to ERP success is a marathon, not a sprint, but the rewards are well worth the effort.

Frequently Asked Questions (FAQ) about ERP software for manufacturing

What are the key benefits of implementing ERP software specifically for a manufacturing business?

Implementing ERP software for manufacturing offers numerous benefits, streamlining processes and boosting efficiency. Improved inventory management is a major advantage, providing real-time visibility into stock levels, minimizing waste, and preventing stockouts. ERP systems also enhance production planning and scheduling, optimizing resource allocation and reducing lead times. Furthermore, manufacturers can experience better cost control through accurate tracking of expenses and improved profitability analysis. Finally, ERP software facilitates better compliance with industry regulations and standards by centralizing data and automating reporting processes. These improvements contribute to increased operational efficiency, reduced costs, and improved customer satisfaction, ultimately leading to higher profitability and a competitive advantage.

How much does it typically cost to implement and maintain an ERP system for a small to medium-sized manufacturing company?

The cost of implementing and maintaining an ERP system for a small to medium-sized manufacturing company can vary significantly based on factors like the software’s complexity, the number of users, customization requirements, and the chosen deployment method (cloud-based vs. on-premise). Initial implementation costs can range from $5,000 to $500,000 or more. This includes software licenses, implementation services (consulting, data migration, training), and hardware (if required). Ongoing maintenance costs, including software updates, support, and potential customizations, usually range from 15% to 25% of the initial software license cost annually. Cloud-based solutions often have lower upfront costs but higher recurring subscription fees. It’s crucial to get detailed quotes from multiple vendors to accurately assess the total cost of ownership before making a decision.

What specific manufacturing processes can ERP software help to improve, such as supply chain management or shop floor control?

ERP software significantly improves various manufacturing processes. In supply chain management, it optimizes procurement, manages supplier relationships, and streamlines logistics. For shop floor control, ERP provides real-time visibility into production activities, allowing for better scheduling, tracking of work orders, and monitoring of machine performance. It also enhances quality control by tracking defects, managing inspections, and ensuring compliance with standards. Inventory management is streamlined through automated tracking of stock levels and optimized reordering points. Furthermore, ERP systems improve materials requirements planning (MRP), ensuring the availability of necessary materials at the right time. By integrating these processes, ERP software enhances efficiency, reduces costs, and improves overall operational performance for manufacturing companies.